If you're managing dock appointments with a whiteboard, shared Excel file, or an Outlook calendar that three people update at the same time — you already know something's off. You just haven't had a reason painful enough to change it yet. Here are five signs that your current setup has hit its limit. If three or more sound familiar, you've outgrown manual scheduling.

1. You're the middleman for every dock appointment

Carriers call to ask what times are open. You check the spreadsheet (or walk to the whiteboard), find an open slot, call them back or send an email. They suggest a different time. You go back and check again.

This loop repeats 20–50 times a day at a typical mid-size facility. That's 15–25 hours per week of coordinator time spent on phone tag and email chains — time that adds up to $24,000–$40,000 a year in scheduling labor alone.

The fix is obvious: let carriers see available times and book their own slots. But you can't do that with a whiteboard.

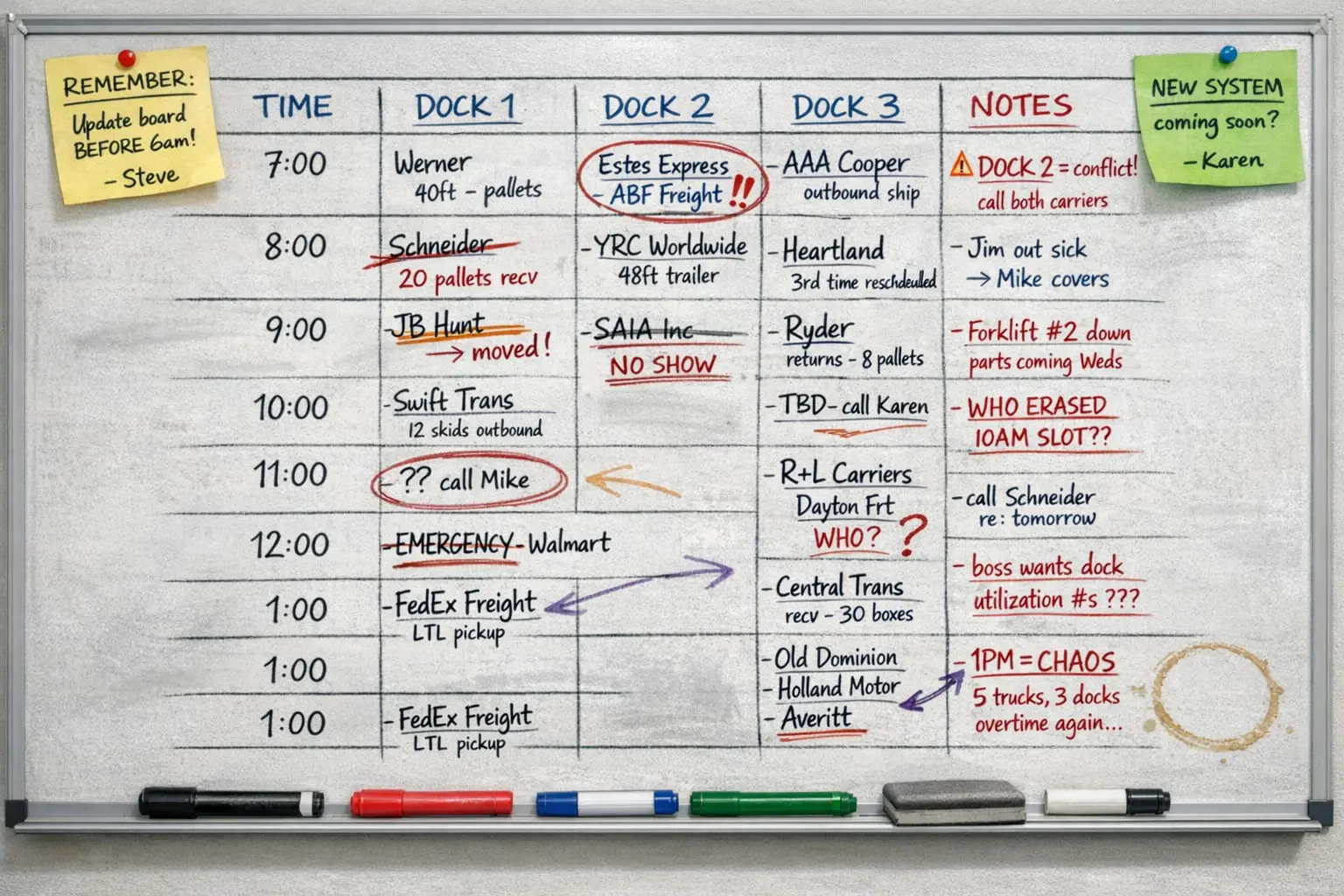

2. Double-bookings keep happening

Two people update the spreadsheet. Or someone erases a line on the whiteboard and writes over it. Or an email confirmation gets buried. Result: two trucks show up at dock 2 at 10 AM, and somebody's waiting.

This isn't a people problem — it's a system problem. Shared spreadsheets and calendars don't lock time slots. There's no live conflict detection. If two coordinators are scheduling at the same time, neither one sees the other's changes until it's too late.

With proper dock scheduling software, each slot can only be booked once. It's a live system. No double-booking is technically possible.

3. You have no data when your boss asks questions

Your boss wants to know: How utilized are our docks? Which carriers are consistently late? How many trucks did we handle last month? What's our average loading time?

You don't know. The whiteboard doesn't remember yesterday. The spreadsheet has gaps. Nobody's tracking timestamps.

This matters more than it used to. ISO audits, customer audits, and insurance reviews increasingly ask for documentation of warehouse operations. If your scheduling data lives on a whiteboard, you have nothing to show.

Dock scheduling software logs everything automatically — arrival times, loading durations, delays, dock utilization. You can export it to Excel or show visual statistics. No extra work required.

4. The afternoon pile-up is getting worse

Mornings start quiet. Then somewhere around 1 PM, every carrier shows up at once. Docks are backed up, the yard is full, and you're looking at overtime to clear the queue before end of shift.

This happens because without scheduled time slots, carriers show up when it's convenient for them — not when it's optimal for your warehouse. There's no mechanism to spread arrivals across the day.

The math is simple: uncontrolled arrivals create congestion spikes that force overtime at 1.5x rates, while docks sit idle during off-peak hours. According to ATRI's 2024 study, 39.3% of all pickup and delivery stops involve detention, costing the trucking industry $15.1 billion annually. That cost gets passed back to shippers — including you — through higher freight rates and detention charges.

Appointment-based scheduling distributes arrivals evenly. The afternoon pile-up flattens. Overtime drops.

5. You've added docks, shifts, or a second facility

The whiteboard worked when you had two docks and one shift. Now you've got four docks across two shifts, or you've opened a second location. The complexity has doubled, but the scheduling method hasn't changed.

Every dock and every shift multiplies the coordination burden. More carriers, more phone calls, more chances for scheduling conflicts. At a certain point, the informal system buckles under its own weight.

This is the most common trigger we see from new customers. Growth exposes what "good enough" was hiding.

It's not just you: how Cleveron made the switch

Cleveron, an Estonian technology company producing robotics-based parcel solutions, was in the same spot. Their warehouse ran on manual coordination — emails to logistics providers, back-and-forth scheduling, no central visibility.

Their COO, Ott Pabut, described what changed after switching to LoadingCalendar alongside Cargoson TMS: scheduling went from a daily email grind to a two-click process. Walk into their warehouse today and you'll see touchscreens displaying the dock schedule in real time — no whiteboards in sight.

The payoff went beyond time savings. Carriers got self-service booking, so they stopped calling to ask about availability. Warehouse staff could prepare for deliveries in advance instead of reacting to whatever showed up. The back-and-forth disappeared.

You can read the full Cleveron customer story here.

What's it actually costing you? Run the numbers.

Most warehouse managers know manual scheduling is inefficient. Few have quantified how expensive it actually is. The costs hide in coordinator overtime, carrier detention invoices, idle docks, and the daily chaos of unplanned arrivals.

LoadingCalendar built a free ROI calculator that puts real numbers on these hidden costs. Plug in your daily truck volume, how many hours your team spends scheduling, and your detention fees — it takes 30 seconds.

The results tend to surprise people. A mid-size facility handling 30 trucks per day typically sees annual savings in the range of $25,000–$40,000 just from reduced scheduling labor and detention fees. At €99/month for LoadingCalendar (flat rate, unlimited docks, users, and carriers), the payback period is measured in days, not months.

The calculator breaks savings into three categories: scheduling labor recovered when carriers self-book, detention fee reduction from pre-confirmed time slots, and overtime savings from flattening arrival peaks. Each assumption is documented and sourced — no black-box math.

What to do about it

If three or more of these signs hit home, you don't need a bigger whiteboard. You need a system where carriers book their own times, slots can't be double-booked, and data gets captured automatically.

LoadingCalendar does exactly that — and not much more, which is the point. No yard management, no gate automation, no six-month implementation project. Flat pricing at €99/month. Unlimited everything. Set up in 5 minutes. 14-day free trial, no credit card required.

Most customers have carriers self-booking within the first two weeks. The ones who take the firm approach — "no booking, no loading" — see full adoption within a month.